A type (Standard type)

Brass/stainless steel rimmed filter screen is a simple structured filter, mostly using two or more layers of stainless steel woven or sintered mesh as the filtration layer, and then rimmed with brass or stainless steel. This filter screen has great high pressure resistance, small and thin. It is often installed in the interface and flange of hydraulic, pneumatic and other fluid devices, to filter various oils and air, protect the downstream key equipment and ensure the machinery operates smoothly.

Brass/stainless steel rimmed filter screen

Category

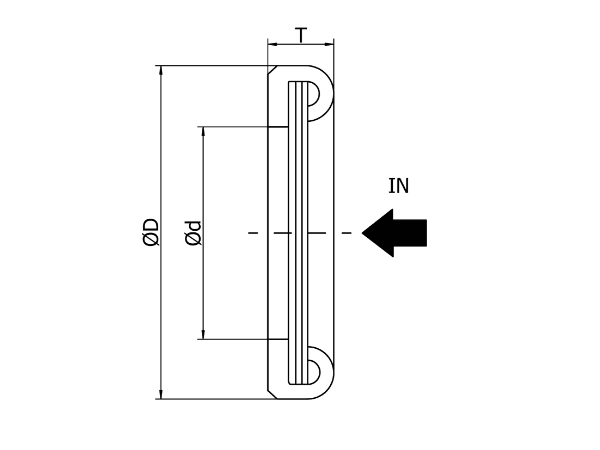

A type (Standard type)

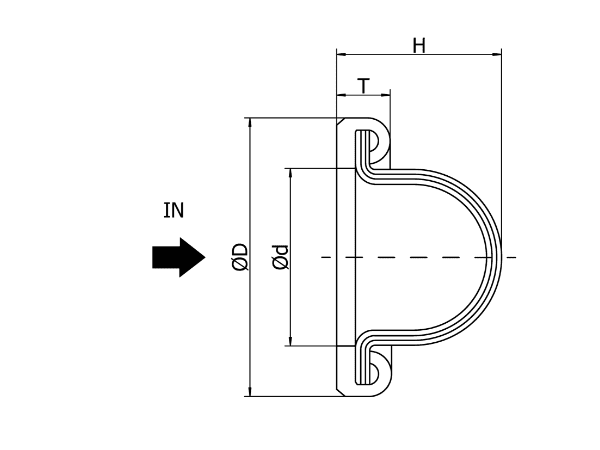

AH type (Filter with increased filtering area)

Filter Mesh Category

Sintered mesh

Mostly used in auto-relief valves of excavators, loaders, bulldozers, mobile crushers and recycling machines

Woven mesh

Mostly used in miniature couplings

Metal pleated mesh

Mostly used in servo valves

Specification

A type (Standard type)

AH type (Filter with increased filtering area)

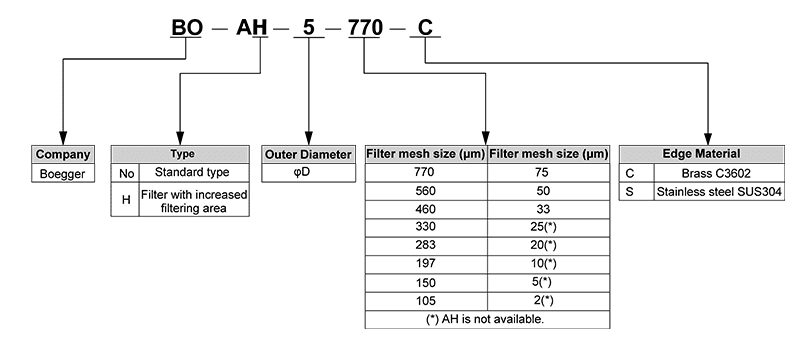

Model Symbol

| Model | Outer Diameter φD (mm) | Inner Diameter φd (mm) | Thickness T±0.1 (mm) | H (AH) (mm) |

|---|---|---|---|---|

| BO-A-5 | 5 | 3.0 | 2.2 | - |

| BO-A-6 | 6 | 3.5 | 2.2 | - |

| BO-A-7 | 7 | 4.0 | 2.2 | - |

| BO-A-8 | 8 | 5.0 | 2.2 | - |

| BO-A-9 | 9 | 6.0 | 2.2 | - |

| BO-A-10 | 10 | 6.5 | 2.2 | 6.0 |

| BO-A-11 | 11 | 7.0 | 2.2 | 6.0 |

| BO-A-12 | 12 | 7.5 | 2.2 | 6.5 |

| BO-A-13 | 13 | 8.0 | 3.0 | 8.0 |

| BO-A-14 | 14 | 8.5 | 3.0 | 8.0 |

| BO-A-15 | 15 | 9.0 | 3.0 | 8.0 |

| BO-A-16 | 16 | 10.0 | 3.0 | 8.0 |

| BO-A-17 | 17 | 11.0 | 3.0 | 9.0 |

| BO-A-18 | 18 | 12.0 | 3.5 | 9.0 |

| BO-A-20 | 20 | 14.0 | 3.5 | 10.0 |

| BO-A-22 | 22 | 15.0 | 3.5 | 12.5 |

| BO-A-25 | 25 | 17.0 | 3.5 | 13.5 |

| BO-A-28 | 28 | 18.0 | 4.0 | 14.0 |

| BO-A-30 | 30 | 21.0 | 4.0 | 15.0 |

| BO-A-32 | 32 | 22.0 | 4.0 | 15.0 |

| BO-A-35 | 35 | 25.0 | 4.5 | 18.0 |

| BO-A-38 | 38 | 28.0 | 4.5 | 18.0 |

| BO-A-40 | 40 | 30.0 | 4.5 | 20.0 |

| BO-A-42 | 42 | 32.0 | 4.5 | 20.0 |

| BO-A-45 | 45 | 35.0 | 5.0 | 20.0 |

| BO-A-48 | 48 | 38.0 | 5.0 | 20.0 |

| BO-A-50 | 50 | 40.0 | 5.0 | 20.0 |

Features

Application