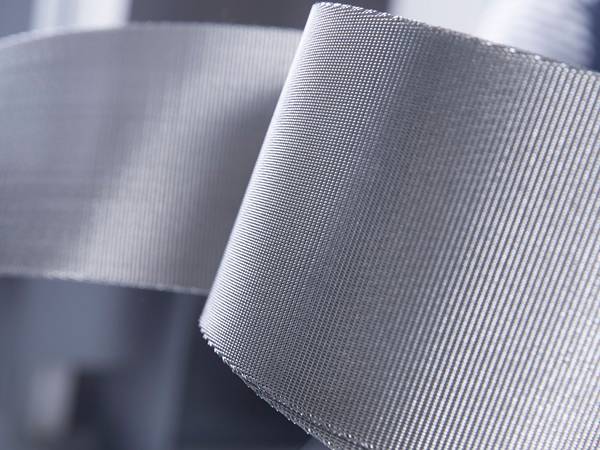

Continuous belt screens, refers to reverse dutch weave filter belts made of stainless steel wires. The continuous (automatic) belt screens are innovation of extruder screens. They are used for screening impurities out of molten plastic. Used with screen changers, the automatic belt filter system allows continuous and uninterrupted production and high filtering performance in cast film and blown film production and other plastic filtering process.

Specifications

CBE-01: continuous belt screens are ideal for continuous screen changers

Advantages:

Applications:

| Mesh Size (warp/inch × weft/inch) | Wire diameter (mm) (warp × weft) | Fineness of filtering (micron) | Weight (kg/m2) | Width (mm) * | Length (m) |

|---|---|---|---|---|---|

| 48 × 10 | 0.5 × 0.5 | 400 | 3.63 | 40–210 | 10,000 |

| 63 × 18 | 0.4 × 0.6 | 220 | 4.14 | 40–210 | 10,000 |

| 72 × 15 | 0.45 × 0.55 | 250 | 4.78 | 40–210 | 10,000 |

| 100 × 16 | 0.35 × 0.45 | 190 | 3.87 | 40–210 | 10,000 |

| 107 × 20 | 0.24 × 0.60 | 210 | 3.34 | 40–210 | 10,000 |

| 120 × 16 | 0.35 × 0.45 | 180 | 4.49 | 40–210 | 10,000 |

| 132 × 17 | 0.32 × 0.45 | 170 | 4.24 | 40–210 | 10,000 |

| 152 × 24 | 0.27 × 0.4 | 160 | 3.73 | 40–210 | 10,000 |

| 160 × 17 | 0.27 × 0.45 | 160 | 2.02 | 40–210 | 10,000 |

| 170 × 18 | 0.27 ×0.45 | 160 | 4.01 | 40–210 | 10,000 |

| 171 × 46 | 0.15 × 0.30 | 130 | 2.00 | 40–210 | 10,000 |

| 180 × 20 | 0.27 × 0.45 | 170 | 4.29 | 40–210 | 10,000 |

| 200 × 40 | 0.17 × 0.27 | 120 | 2.17 | 40–210 | 10,000 |

| 240 × 40 | 0.15 × 0.25 | 70 | 1.98 | 40–210 | 10,000 |

| 260 × 40 | 0.15 × 0.27 | 55 | 2.19 | 40–210 | 10,000 |

| 290 × 76 | 0.09 × 0.19 | 40 | 1.27 | 40–210 | 10,000 |

| 300 × 40 | 0.15 × 0.25 | 50 | 2.31 | 40–210 | 10,000 |

| 300 × 80 | 0.15 × 0.2 | 35 | 2.49 | 40–210 | 10,000 |

| Special specifications can be customized upon customers' requirements * Maximum width is 500 mm. |

|||||