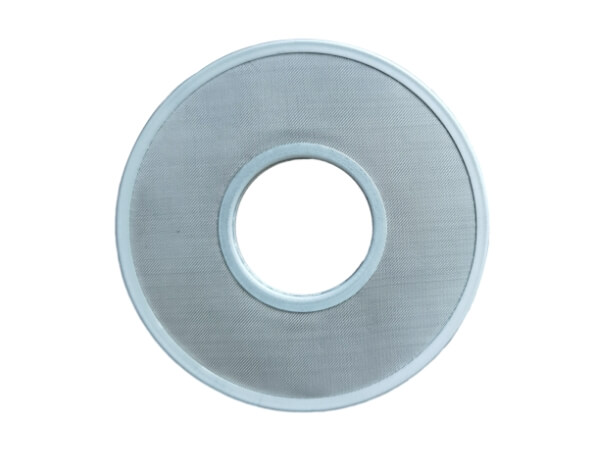

Detail display

SPL & DPL filter element is a double cylinder filter element used in high viscosity melt filtration units. It is made of stainless steel sintered felt and stainless steel sintered mesh, which can easily remove hard impurities and coagulation. Among them, SPL & DPL filter elements can be reused and cleaned many times, which is economical and environmentally friendly.

SPL & DPL filter elements are mainly used for oil filtration in filter presses, filtration of oil systems in ships, diesel engines, and other equipment, and filtration of impurities in textile stocks in the chemical fiber industry on the front side of spinning nozzles of various types for the textile use of synthetic and man-made fibers and under other similar conditions. In these application scenarios, SPL & DPL filter elements can effectively filter out impurities and particles in the oil to protect the regular operation of the equipment. For applications in the textile industry, SPL & DPL filter elements also improve the quality of textiles, ensuring that they are produced free of impurities and defects.

Features

Specification

| SPL Modes | DPL Modes | Strainer DN (mm) |

Rated Flow (L/min) |

Filter Precision (μm) |

Nominal Pressure (MPa) |

Inner Disc Size (mm) |

Outer Disc Size (mm) |

Filter Disc Number |

|---|---|---|---|---|---|---|---|---|

| BD-SPL15 | - | 15 | 33.4 | 30 40 80 100 180 200 280 |

0.8 | 20 | 40 | 2–30 |

| BD-SPL25 | BD-DPL25 | 25 | 83.4 | 30 | 65 | 2–30 | ||

| BD-SPL32 | - | 32 | 134 | 30 | 65 | 2–30 | ||

| BD-SPL40 | BD-DPL40 | 40 | 200 | 45 | 90 | 2–34 | ||

| BD-SPL50 | - | 50 | 334 | 60 | 125 | - | ||

| BD-SPL65 | BD-DPL65 | 65 | 500 | 30 | 65 | 2–34 | ||

| BD-SPL80 | BD-DPL80 | 80 | 834 | 70 | 155 | 2–40 | ||

| BD-SPL100 | - | 100 | 1334 | 70 | 155 | 4–40 | ||

| BD-SPL125 | - | 125 | 2000 | 90 | 175 | 4–40 | ||

| BD-SPL150 | BD-DPL150 | 150 | 3000 | 90 | 175 | 6–40 | ||

| BD-SPL200 | BD-DPL200 | 200 | 5334 | 90 | 175 | 8–40 | ||

|

||||||||

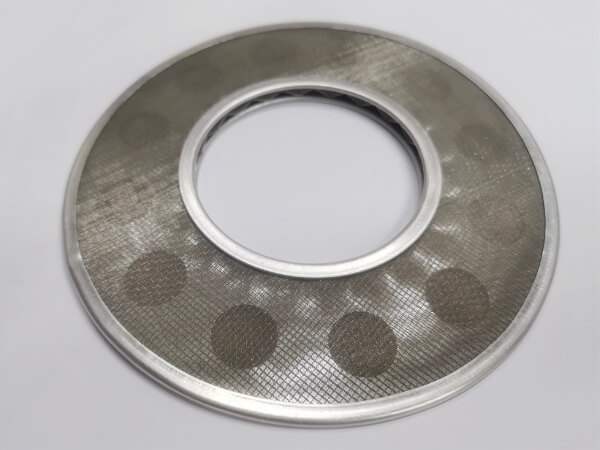

Products Display

Detail display

SPL & DPL filter element thickness measurement

SPL & DPL filter element edge size measurement

SPL & DPL filter element diameter measurement

Finished SPL & DPL filter element

SPL & DPL filter elements packaging