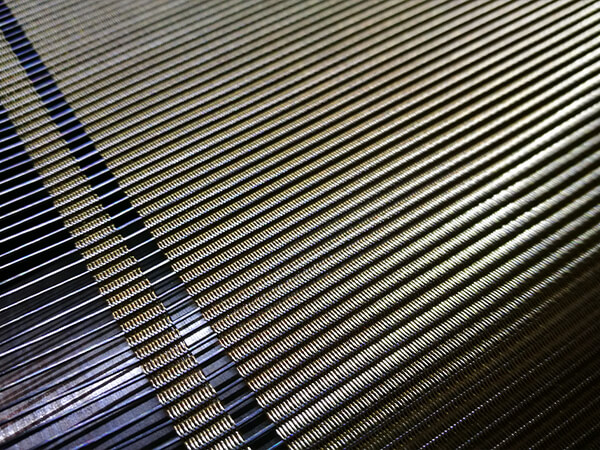

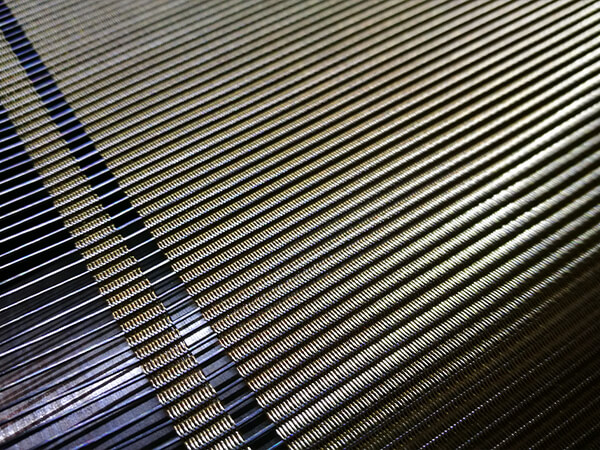

Warp and weft wires

Copper clad steel wire mesh, also known as melt filter band for automatic filter changers, is made of copper clad steel and manufactured using a reversed Dutch weave technique. It possesses numerous advantages, including high tensile strength, excellent corrosion resistance, precise filtration, structural stability, and a long service life. It is commonly used in polymer extrusion. plastic/rubber production/recycling/filtration, film production, and other applications.

COE-01: Copper extruder disc has good filter efficiency.

Specification

Feature

Warp and weft wires

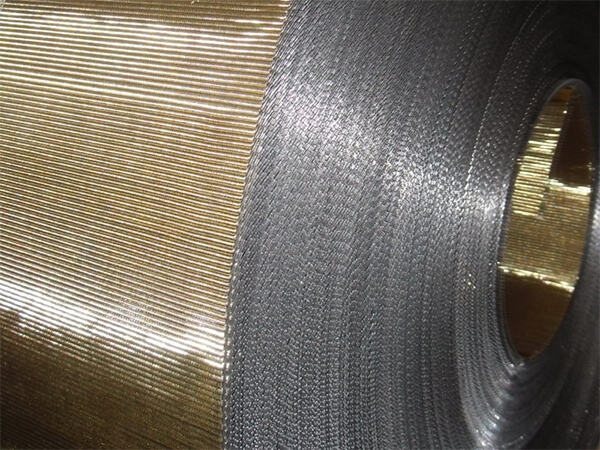

Plastic film packaging

Top view

Inner view

Packaging

Kraft paper to prevent moisture → Foam paper to prevent hard objects from choking → Plastic film to prevent water and moisture → Put copper clad steel wire mesh into plywood crate → Tie-die.

RFQ: