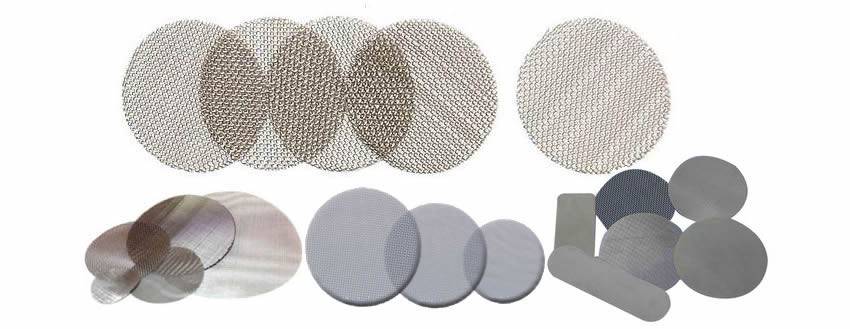

CIS-01: Single layer extruder screens in round shape

Circle Extruder screens are available in different size, variants and specifications. They are highly durable with robust structure and have features of anti-abrasive and anti-corrosive in single layer and muti-layer.

They are predominantly used in the extruded profiles and blown film industries where the contamination of the raw material is less and there is often lower pressure within the extruder head.

CIS-01: Single layer extruder screens in round shape

CIS-02: Single layer circle extruder screen is easy to install and clean.

CIS-03: Extruder discs with frame have smooth edges.

CIS-04: Black wire cloth circle extruder screens are cost-effective.

CIS-05: Circle extruder screens can be made from diverse materials.

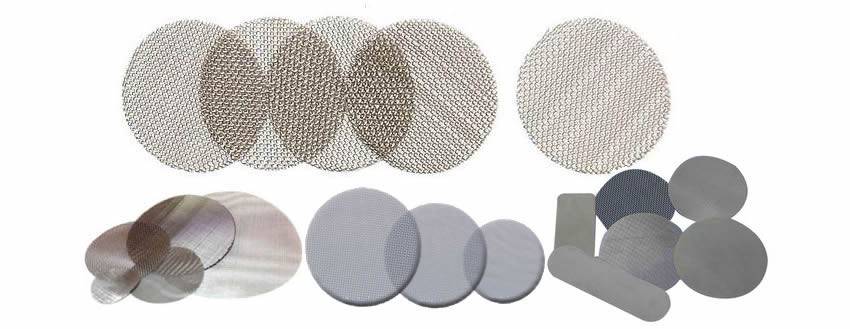

Many single layer screens are assembled properly and spot welded with each other to form multilayer. It can be with or without selvage. Multilayer extruder screen is used for fine and thin level of extrusion to prevent the mixing of foreign particles. Multilayer Extruder Screen helps in making extrusion more clear and clean.

CIS-06: Multilayer circular screens and screen pack

CIS-07: Multilayer circle extruder screen has high filter precision.

CIS-08: Multilayer circle extruder screens with rims have stable structure.

Size table:

| Mesh Count | Wire Diameter (mm) | Aperture (mm) |

|---|---|---|

| 6 × 6 | 0.900 | 3.31 |

| 10 × 10 | 0.56 | 1.98 |

| 20 × 20 | 0.4 | 0.9 |

| 30 × 30 | 0.28 | 0.57 |

| 40 × 40 | 0.224 | 0.411 |

| 50 × 50 | 0.20 | 0.31 |

| 60 × 60 | 0.16 | 0.263 |

| 80 × 80 | 0.14 | 0.178 |

| 100 × 100 | 0.112 | 0.142 |

| 120 × 120 | 0.09 | 0.122 |

| 150 × 150 | 0.063 | 0.109 |

| 12/72 | 0.50/0.375 | 0.300 |

| 24/110 | 0.355/0.25 | 0.125 |

| 50/250 | 0.14/0.11 | 0.063 |

Hot specifications ordered by customers:

Circle extruder screens benefits:

Applications of circle extruder screen: