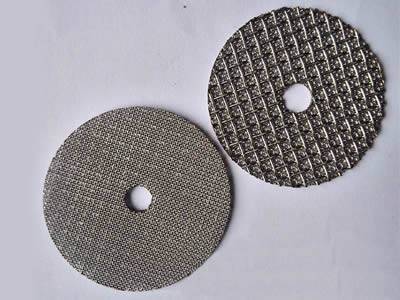

SIE-02: Sintered extruder screen has good rigidity.

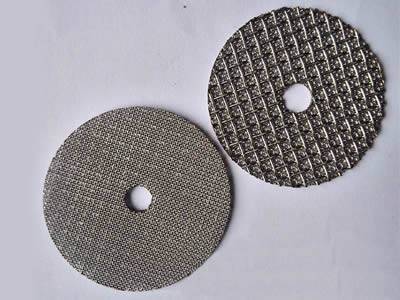

Sintered extruder screens are made from multiple layers metal wire mesh which give the screen good hardness and dirt holding capacity.

With high filter precision, sintered extruder screens are used for fine filtration in plastic products, chemical, medicine, metallurgy industries. And we can design and match various precision of wire mesh into different extruder screen types according to your needs.

Specifications of sintered extruder screen:

SIE-01: Sintered extruder discs are durable.

Sintered extruder screen features:

Sintered extruder screen applications:

SIE-02: Sintered extruder screen has good rigidity.

SIE-03: Sintered extruder screen can be square sheet.

SIE-04: With high strength, thick sintered extruder screen is strong with dutch weave screen as the outermost layer.

SIE-05: Cylindrical sintered extruder screen possesses large dirt holding capacity.