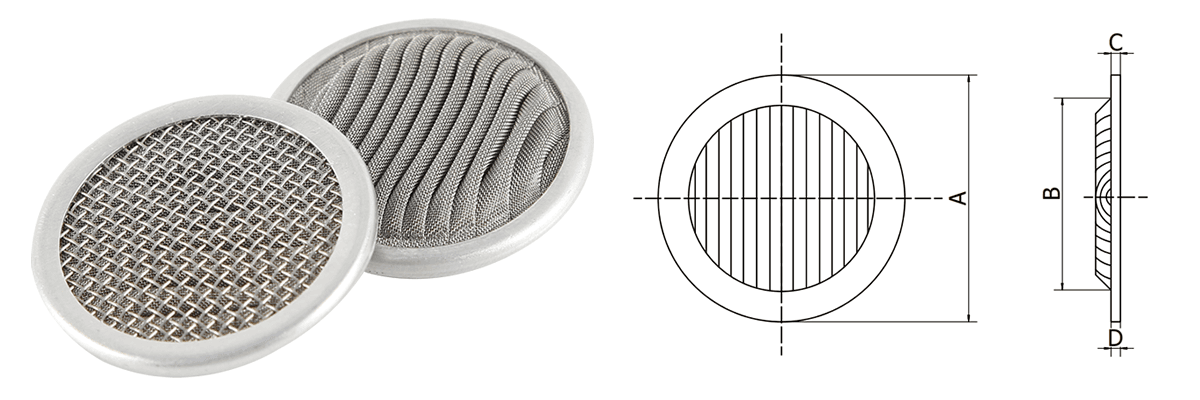

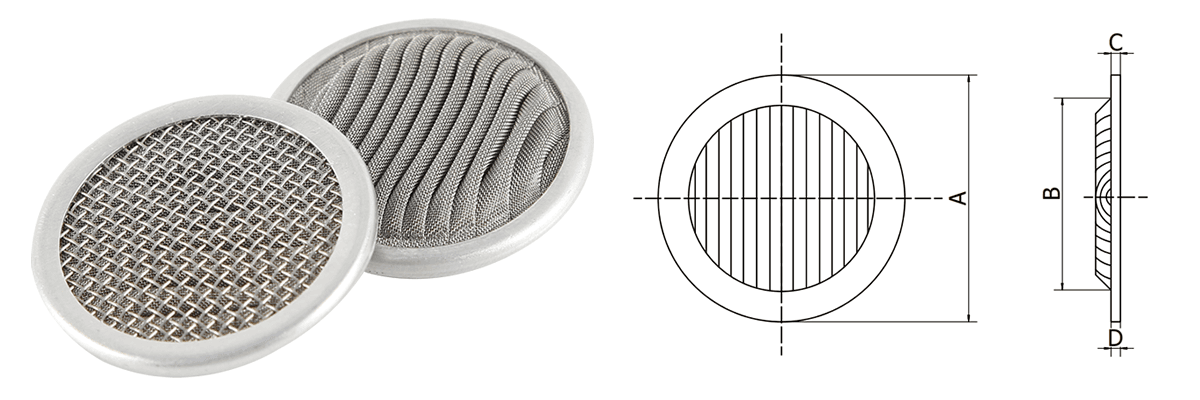

Pleated side + plain side

Pleated filter discs, also called extended area screen, are designed to provide a compact,lightweight element for reliable economical filtration protection in various critical areas of a system to remove contaminants which might otherwise clog or damage control components.

Pleated filter discs are made from stainless steel wire mesh or other alloy mesh to form a solid single or multiple layers structure. And you can customize various types of pleated filter screens that meet applications.

Featured with large filter area and good hardness, pleated extruder screen can give long services for extruder and filter industries. Even in high temperature or high pressure, it also can ensure materials purity.

Structure Options

Pleated side + plain side

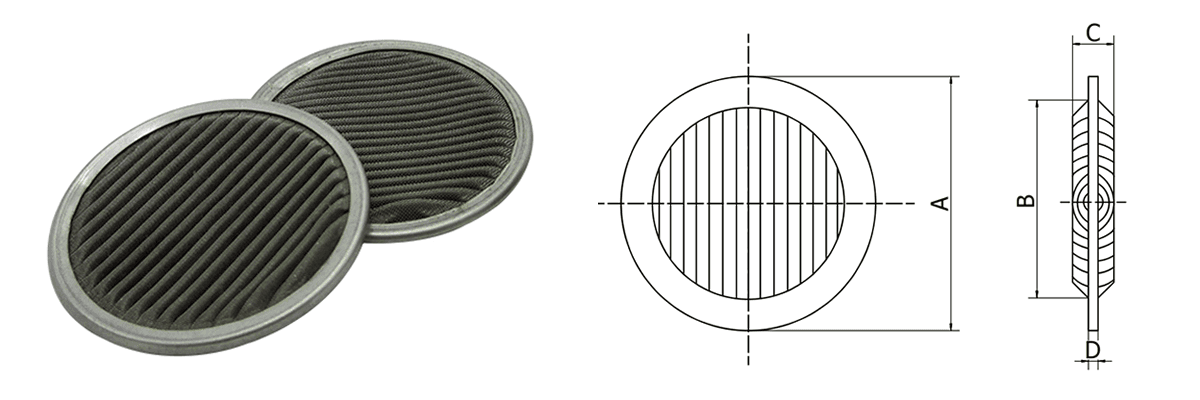

Pleated side + pleated side

Gaskets Options

Pleated filter disc without gaskets.

Pleated filter disc with stainless steel gaskets.

Sealing Ring Options

Stainless steel gaskets.

Copper gaskets.

Brass gaskets.

Specifications

| Item | Dimensions | Effective Area in2 | |||

|---|---|---|---|---|---|

| A±.005" | B±.015" | C±.015" | D±.015" | ||

| 1 | .375 | .300 | .100 | .030 | .22 |

| 2 | .500 | .420 | .150 | .040 | .66 |

| 3 | .625 | .490 | .170 | .060 | 1.00 |

| 4 | .750 | .615 | .170 | .060 | 1.60 |

| 5 | 1.000 | .875 | .170 | .060 | 3.30 |

| 6 | 1.375 | 1.250 | .170 | .060 | 6.60 |

| Note: A – O.D. (Outer Diameter) B – I.D. (Inner Diameter) C – Overall Thickness D – Boarder Thickness |

|||||

| Micron code | Nominal | Absolute |

| 2X | 2 | 10 |

| 2 | 2 | 15 |

| 5 | 5 | 20 |

| 10 | 10 | 25 |

| 20 | 20 | 40 |

| 40 | 40 | 75 |

| 75 | 75 | 100 |

| 100 | 100 | 150 |

| 200 | 200 | 300 |

| Micron rating is based on retention of particles whose two smallest dimensions exceed the specified rating | ||

Features

Applications

Accurately filter high polymer melts such as chemical fiber, molten glass, ceramics, etc. Show its abilities in petrochemical, metallurgy, medicine industries.