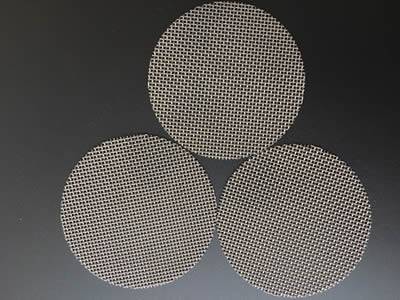

PWE-01: Plain weave extruder disc has simple structure that is easy to operate.

Plain weave extruder screen is commonly made from stainless steel wire that has excellent resistance to rust, abrasion and corrosion.

As the common type of filter screen, plain extruder screens are cost-effective and can meet most of filter requirements in plastic products, petrochemical, ceramics, rubber industries. Of course, the mesh fine level can be customized.

PWE-01: Plain weave extruder disc has simple structure that is easy to operate.

PWE-02: Thick pain weave extruder discs has high strength.

Specifications of plain weave extruder screen:

Plain weave extruder screen features:

Plain weave extruder screen applications:

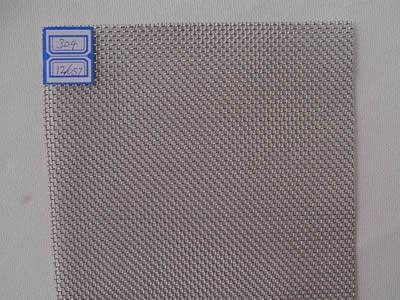

PWE-03: Woven extruder screens can be supplied in square sheets.

PWE-04: Extruder screen packs shapes and sizes all can be customized on demand.