Fluid Filtration Gaskets

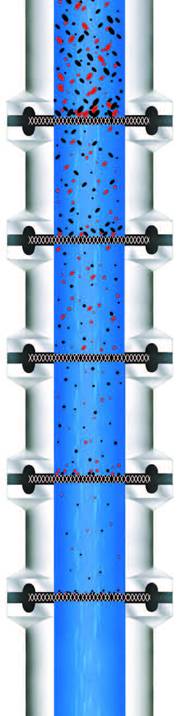

Tri-clamp screen gaskets are designed to be interchangeable with standard sanitary clamp gaskets to protect pump, values and other components in fluid line.

It has the widest ranges of mesh sizes for excellent and efficient particulates collection and filtration in water, acetones and ketones transmission.

EPDM, PTFE, viton and silicon gasket material options supply perfect performance in corrosive and chemical fluid transmission.

Screen Gasket Types

Fluid Filtration Gaskets

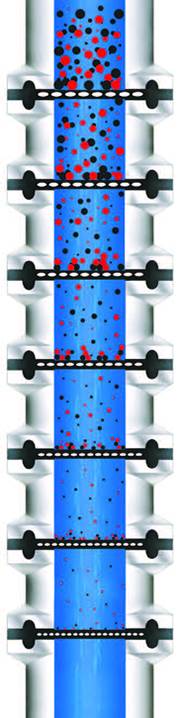

Perforated Plate Gaskets

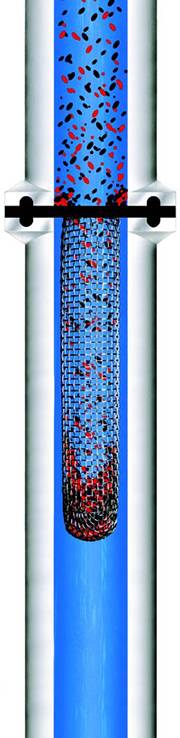

Sock Screens

|

||||||

| Size | Inside Diameter (I.D.) | Outer Diameter (O.D.) | Bead Diameter | |||

|---|---|---|---|---|---|---|

| 1/2" | 0.40" | 10.2 mm | 0.87" | 22 mm | n/a | n/a |

| 3/4" | 0.64" | 16.2 mm | 0.87" | 22 mm | n/a | n/a |

| 1" | 0.90" | 22.9 mm | 2.00" | 50.5 mm | 1.71" | 43.5 mm |

| 1-1/2" | 1.39" | 35.3 mm | 2.00" | 50.5 mm | 1.71" | 43.5 mm |

| 2" | 1.88" | 47.8 mm | 2.52" | 64 mm | 2.22" | 56.5 mm |

| 2-1/2" | 2.39" | 60.5 mm | 3.05" | 77.5 mm | 2.78" | 70.5 mm |

| 3" | 2.88" | 73.1 mm | 3.58" | 91 mm | 3.29" | 83.5 mm |

| 4" | 3.85" | 97.7 mm | 4.67" | 119 mm | 4.33" | 110 mm |

| 5" | 4.86" | 123.5 mm | 5.68" | 144.2 mm | 5.29" | 134.3 mm |

| 6" | 5.80" | 147.2 mm | 6.57" | 167 mm | 6.16" | 156.5 mm |

| 8" | 7.80" | 198 mm | 8.56" | 217.4 mm | 8.15" | 207 mm |

| 10" | 9.74" | 247.4 mm | 10.55" | 268 mm | 10.12" | 257 mm |

| 12" | 11.74" | 298.2 mm | 12.56" | 319 mm | 12.17" | 309 mm |

Note: special orders are also available: metal detectable elastomer, special screen materials, large diameters and fine meshes.

This fluid filtration gaskets are made of stainless steel wires in plain or dutch weave meshes. The high quality stainless steel material make them suitable for high purity system even in the harshest environments.

The fluid filtration screen gaskets are available in a variety of mesh sizes ranging from 4 mesh to 325 mesh. The most wide ranges of mesh options can provide the ultimate particulate elimination and satisfy all your primary, medium and final filtration in many process equipment.

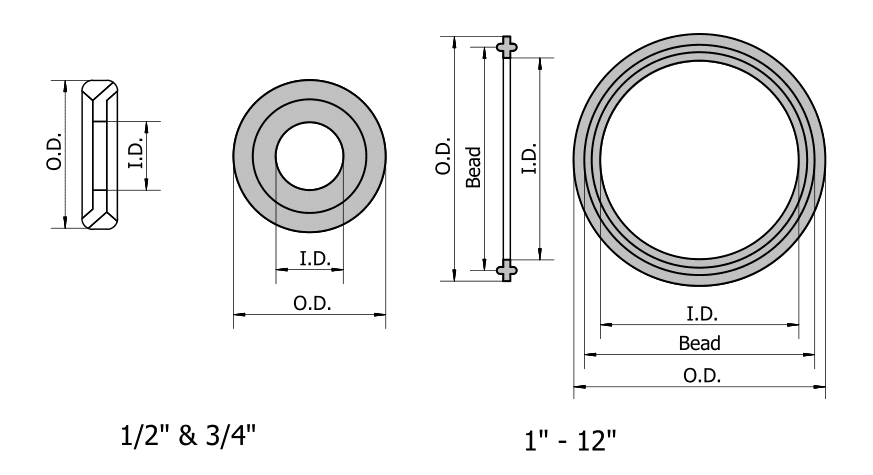

Dimensions

Plain weave screen gaskets.

Dutch weave screen gaskets.

| Mesh Counts | Diameter | Opening | ||

|---|---|---|---|---|

| mesh/inch | mm | inch | mm | inch |

| 10 | 0.6 | 0.024 | 1.94 | 0.076 |

| 20 | 0.4 | 0.016 | 0.87 | 0.034 |

| 20 | 0.45 | 0.018 | 0.82 | 0.032 |

| 40 | 0.2 | 0.008 | 0.44 | 0.017 |

| 60 | 0.16 | 0.006 | 0.26 | 0.01 |

| 60 | 0.19 | 0.007 | 0.23 | 0.009 |

| 80 | 0.12 | 0.005 | 0.2 | 0.008 |

| 80 | 0.13 | 0.005 | 0.19 | 0.007 |

| 100 | 0.1 | 0.004 | 0.15 | 0.006 |

| 100 | 0.11 | 0.004 | 0.14 | 0.006 |

| 120 | 0.09 | 0.004 | 0.12 | 0.005 |

| 120 | 0.058 | 0.002 | 0.15 | 0.006 |

| 120 | 0.08 | 0.003 | 0.13 | 0.005 |

| 140 | 0.07 | 0.003 | 0.11 | 0.004 |

| 160 | 0.05 | 0.002 | 0.11 | 0.004 |

| 160 | 0.04 | 0.002 | 0.12 | 0.005 |

| 160 | 0.035 | 0.001 | 0.12 | 0.005 |

| 180 | 0.05 | 0.002 | 0.09 | 0.004 |

| 180 | 0.04 | 0.002 | 0.1 | 0.004 |

| 200 | 0.053 | 0.002 | 0.07 | 0.003 |

| 200 | 0.05 | 0.002 | 0.08 | 0.003 |

| 200 | 0.04 | 0.002 | 0.09 | 0.003 |

| 220 | 0.05 | 0.002 | 0.07 | 0.003 |

| 280 | 0.035 | 0.001 | 0.06 | 0.002 |

| 300 | 0.03 | 0.001 | 0.05 | 0.002 |

| 325 | 0.025 | 0.001 | 0.05 | 0.002 |

| 325 | 0.028 | 0.001 | 0.05 | 0.002 |

| 325 | 0.03 | 0.001 | 0.05 | 0.002 |

Tri-clamp perforated plate screen gaskets are manufactured with 22 gauge stainless steel plates, which are trapped into the gasket body.

Perforated sanitary gaskets are designed as pre-filters for expensive membrane filters or straining particulate in fill and finish products, particulate removal in a numbers or process in industries.

Here are different perforations options, which can satisfy different filtration fineness and dust collection requirements.

Dimensions

| Perforation Diameter | Center Type | Holes/in² | Open Area (%) |

|---|---|---|---|

| 0.033" | 0.055" Straight Line Centers | 330 | 29% |

| 0.045" | 0.066" Straight Line Centers | 225 | 37% |

| 0.062" (1/16") | 0.094" Straight Line Centers | 132 | 41% |

| 0.094" (3/32") | 0.156" Straight Line Centers | 46 | 33% |

| 0.125" (1/8") | 0.187" Straight Line Centers | 33 | 40% |

| 0.187" (3/16") | 0.250" Straight Line Centers | 18 | 50% |

| 0.250" (1/4") | 0.375" Straight Line Centers | - | 40% |

Features

Applications

Sock screen strainers, inserted into the I.D. of stainless steel tubing, are designed for high volume applications with low pressure drop to provide filtration for greater soil retention. The extended sock shaped mesh gasket offers up to 300% more open area for 300% more soil collection capacity than conventional screens.

Sock screens can provide a greater flow and better particulates filtration for expensive processing pumps and equipment. They effectively decreasing pump wear and burnout while increasing energy conservation. Moreover, the stable structure and high quality products requires less maintenance to save down time and maintenance costs.

Dimensions

| Mesh Counts | Diameter | Opening | ||

|---|---|---|---|---|

| mesh/inch | mm | inch | mm | inch |

| 10 | 0.6 | 0.024 | 1.94 | 0.076 |

| 20 | 0.4 | 0.016 | 0.87 | 0.034 |

| 20 | 0.45 | 0.018 | 0.82 | 0.032 |

| 40 | 0.2 | 0.008 | 0.44 | 0.017 |

| 60 | 0.16 | 0.006 | 0.26 | 0.01 |

| 60 | 0.19 | 0.007 | 0.23 | 0.009 |

| 80 | 0.12 | 0.005 | 0.2 | 0.008 |

| 80 | 0.13 | 0.005 | 0.19 | 0.007 |

| 100 | 0.1 | 0.004 | 0.15 | 0.006 |

| 100 | 0.11 | 0.004 | 0.14 | 0.006 |

| 120 | 0.09 | 0.004 | 0.12 | 0.005 |

| 120 | 0.058 | 0.002 | 0.15 | 0.006 |

| 120 | 0.08 | 0.003 | 0.13 | 0.005 |

| 140 | 0.07 | 0.003 | 0.11 | 0.004 |

| 160 | 0.05 | 0.002 | 0.11 | 0.004 |

| 160 | 0.04 | 0.002 | 0.12 | 0.005 |

| 160 | 0.035 | 0.001 | 0.12 | 0.005 |

| 180 | 0.05 | 0.002 | 0.09 | 0.004 |

| 180 | 0.04 | 0.002 | 0.1 | 0.004 |

| 200 | 0.053 | 0.002 | 0.07 | 0.003 |

| 200 | 0.05 | 0.002 | 0.08 | 0.003 |

| 200 | 0.04 | 0.002 | 0.09 | 0.003 |

| 220 | 0.05 | 0.002 | 0.07 | 0.003 |

| 280 | 0.035 | 0.001 | 0.06 | 0.002 |

| 300 | 0.03 | 0.001 | 0.05 | 0.002 |

| 325 | 0.025 | 0.001 | 0.05 | 0.002 |

| 325 | 0.028 | 0.001 | 0.05 | 0.002 |

| 325 | 0.03 | 0.001 | 0.05 | 0.002 |

Features

Applications